- Home

- Commercial

- Industrial

- Inventory/Rental

- Service/Parts

- Training/Resources

- Contact/About

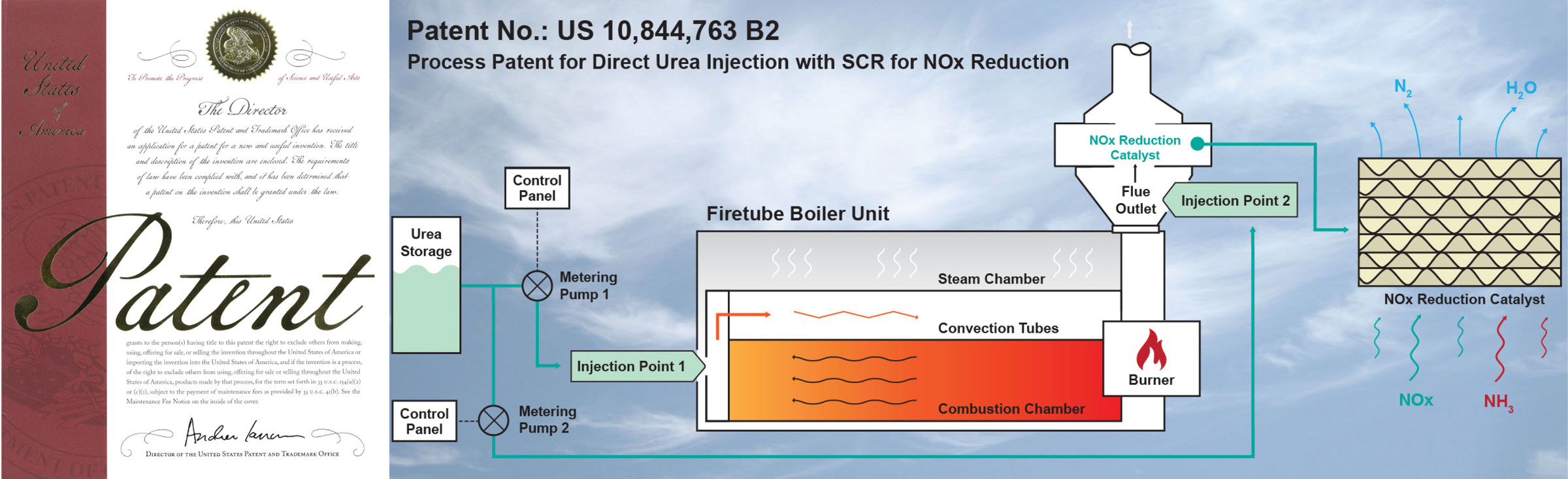

U.S. Patent & Trademark Office Issues Process Patent to RFMCO for Direct Urea Injection with SCR Technology

U.S. Patent & Trademark Office Issues Process Patent to RFMCO for Direct Urea Injection with SCR Technology

With the help of Michael MacDonald and the Boiler Special Projects Group, R.F. MacDonald Co. has invented and now patented the safest NOx emissions reduction process for boilers and fired vessels using direct urea injection with SCR.

On Tuesday, Nov. 24, 2020, the U.S. Patent and Trademark Office issued the safest and simplest NOx-reduction process patent for packaged boilers. The patent was granted to R.F. MacDonald Co. for inventing a “process for direct urea injection with selective catalytic reduction (SCR) for NOx reduction in hot gas streams and related systems and assemblies.”

SCR requires the use and storage of ammonia-based reagents, which range from high risk to low risk. The R.F. MacDonald Co. patent specifies urea, which is the lowest risk ammonia-based reagent. The only health hazard associated with urea is “possible irritation” as indicated by the Hazardous Materials Identification System (HMIS). The urea solution is identical to Diesel Exhaust Fluid (DEF), which is sold worldwide in automotive retail stores for use in diesel motor vehicles.

As shown in the graphic below, urea is injected at each Injection Point into the boiler. As NOx and urea pass through the NOx Reduction Catalyst, NOx is separated into two non-harmful elements Nitrogen (N2) and water (H2O). Read More

We offer several different boiler and pump training courses throughout the year at many different California and Nevada locations. Choose a class and date for more information.

FEBRUARY 19/20 – LAS VEGAS, NV

FEBRUARY 19/20 – LAS VEGAS, NV

MARCH 17/18 – MODESTO, CA

APRIL 21/22 – SAN DIEGO, CA (CANCELED)

APRIL 23/24 – SAN DIEGO, CA (CANCELED)

JULY 14/15 – HAYWARD, CA (CANCELED)

JULY 16/17 – HAYWARD, CA (CANCELED)

SEPTEMBER 22/23 – RENO, NV (CANCELED)

OCTOBER 13/14 – SANTA FE SPRINGS, CA (CANCELED)

OCTOBER 15/16 – SANTA FE SPRINGS, CA (CANCELED)

DECEMBER 8/9 – ROHNERT PARK, CA (CANCELED)

ASK TO BE ON THE WAITLIST VIA INFO@RFMACDONALD.COM

Don Williams Corporate Trainer

Don Williams Corporate Trainer

Don Williams is R.F. MacDonald Co.’s Boiler Division Corporate Trainer. Williams has been in the boiler business for 45 years as a boiler operator, design engineer, service manager and now as a corporate trainer. Williams also performs custom, onsite training where he performs site-specific and equipment-specific training. Each presentation begins with a site visit with identification of boiler system and application needs. Williams then presents a detailed analysis on the customer’s boiler and burner design, controls for operator interface, combustion basics and a breakdown on how to operate and maintain the boiler equipment. You may sign up for one of Don Williams’ CWEA and AFE-certified training classes or email info@rfmacdonald.com for custom, onsite training.

R.F. MacDonald Co. was founded in 1956. We have 270 employees and ten offices throughout California and Nevada. We service and sell boilers, pumps, composites and accessories for commercial and industrial applications. Our employees are sales engineers, full-time mechanical engineers, long-time parts specialists and field service personnel.

R.F. MacDonald Co. was founded in 1956. We have 270 employees and ten offices throughout California and Nevada. We service and sell boilers, pumps, composites and accessories for commercial and industrial applications. Our employees are sales engineers, full-time mechanical engineers, long-time parts specialists and field service personnel.

Our efforts to proactively promote our field service capabilities are a key differentiator between our company and other equipment sales companies. Our customers expect and deserve prompt professional service for the products we provide, and we work enthusiastically to meet and exceed their expectations.

We invite you to review all of our boiler, pump and corrosion resistant products and encourage you to contact an office near you to speak directly with a local representative who can personally assist you with your equipment needs.

R.F. MacDonald Co. will continue to be the leader in market share, sales volume, technological innovation and service capabilities for the mutual benefit of our company, employees, customers and principal suppliers in the markets we serve. We will continue to pursue these goals through integrity and persistence.

An objective for all of us in life is to potentially leave a part of ourselves as we depart this life for another. There are many adjectives that can be used to describe our founder Bob MacDonald but perhaps none more appropriate than ‘persistent.’

An objective for all of us in life is to potentially leave a part of ourselves as we depart this life for another. There are many adjectives that can be used to describe our founder Bob MacDonald but perhaps none more appropriate than ‘persistent.’

From Bob’s personal desk to the growth of our ten-office company, and ultimately his fight with cancer, persistence was his unwavering theme. In the memory of our founder, may these words by Calvin Coolidge be an inspiration to you.

Nothing in the world

can take the place of persistence.

Talent will not;

nothing is more common than

unsuccessful men with talent.

Genius will not;

unrewarded genius is almost a proverb.

Education will not;

The world is full of educated derelicts.

Persistence and determination

alone are omnipotent.

The slogan ‘Press On’ has solved

and always will solve

the problems of

the human race.

R.F. MacDonald Co. strives to be the most experienced company in the industry we serve, and we believe we are meeting the mark.

Vision Statement: “To provide a superior growth oriented workplace environment, that attracts and retains the best employees in the industry, fostering an attitude that provides our customers with the most innovative, responsive and results oriented effort possible.”

1956 - Present Company History

100%

Boiler & Accessory Products Line Card (CA & NV)

100%

Boiler & Accessory Products Line Card (Las Vegas, NV)

100%

Boiler Equipment Maintenance Plans

100%

Boiler Service & Repair Brochure

100%

Commercial Products Line Card

100%

Corporate Capabilities Brochure

100%

Fabrication Capabilities Brochure

100%

Industrial Pump & Accessory Products Line Card

100%

Parts Line Card (Northern CA)

100%

Parts Line Card (Southern CA)

100%

Pump & Rotating Equipment Repair Brochure

100%

SCR Low NOx Solutions & Support Brochure

100%

R.F. MacDonald Co. has been in business since 1956. We service and sell boilers, pumps and accessories for commercial and industrial applications. Our employees are full-time mechanical engineers, sales engineers, parts experts and field service personnel. Allow us to assist you in your equipment selections, installation planning, layout, permitting and project supervision.

General Engineering Contractor A-1

CA: C-4 | NV: C-1

Contractor License

CA: #220117 | NV: #0042816

Replacing old high-pressure pumps with a cost-effective pumping

This content is password protected. To view it

25920 Eden Landing Rd.

Hayward, California 94545

Phone:510-784-0110

Website:https://rfmacdonald.com

| © 2023 R.F. MacDonald Co. All Rights Reserved | Terms and Conditions | Privacy Policy | Contact Us |

|---|